Challenge

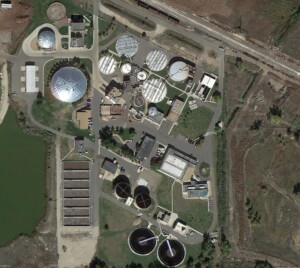

Founded in 1870, Longmont, Colorado, located within Boulder County, is a city of 22 square miles. Longmont sits at an elevation of 4,979 feet above sea level. It is located 37 miles north of Denver, 16 miles east of Boulder, and 30 miles from Rocky Mountain National Park. Longmont was spending about $600,000 per year to haul away liquid and thickened biosolids. The plant’s 40-year-old belt filter press could only handle 35% of the liquid biosolids generated. They needed a system that had the capacity to handle 100% of their biosolids. However, the new system had to be constructed without impeding the flow of tanker trucks used in the removal of liquid biosolids.

The existing facility, constructed in 1956, also had structures that had reached the end of their useful life and could not treat ammonia to a level that would meet the new discharge permit requirements issued in 2012. Aeration tanks and clarifiers needed to be replaced while the plant remained in operation.

Approach

Having completed other successful projects in the past using fixed-price design-build, the City opted to use a hybrid of the progressive design-build delivery method for this project. The Carollo Design-Build Group, a general partnership between Carollo Engineers, Inc., and PCL Construction, Inc., was selected through a two-stage procurement.

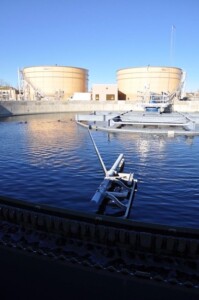

In 2013, Longmont voters allowed the City to issue $32 million in bonds to upgrade their wastewater treatment plant. Shortly after the project began, the City elected to make changes to their original approach to project implementation. The flexibility of progressive design-build delivery allowed the team to incorporate these changes seamlessly. The Carollo Design-Build Group designed, permitted, and constructed a centrifuge process that has the capacity to treat 100% of the biosolids generated by the facility. This included the centrifuge, a truck loading bay, truck scale, and liquid return. The Carollo Design-Build Group also designed and constructed replacement aeration basins and clarifiers sized to provide the required treatment. Construction was completed in a phased approach to ensure that the plant continued to meet effluent requirements throughout construction.

Results

Working closely with the plant operations staff, the Carollo Design-Build Group engineered and constructed a solution that allowed the replacement of existing aeration and clarifiers with minimal disruption to the operation of the facility. It was vital that the plant continued to meet its permit requirements throughout the construction phase. The new aeration and clarifier tanks allow the City to reduce ammonia concentrations to a level that meets its discharge permit requirements for discharge to the St. Vrain River. Now, instead of spending $600,000 per year to haul away liquid biosolids, the City now anticipates only spending $325,000 to haul away drier biosolids.